Scope

We have a client that is operating a Coal mine and power station in an aquifer notorious for Iron bacteria which poses constant issues for their dewatering and water supply operations. If they bores drop in yield or pumps fail mining stops, similar if water supply from the dewatering bore field ceases to the power station the generators are shut off so it was critical we come up with a maintenance program that would allow them to remain operational 24/7.

Description

-

-

- During routine power station shutdowns (twice per year) we carry out maintenance activities on the bores and pumping infrastructure which includes.

-

- Removal of pumps and downhole equipment from the bores. Pumps range from 26-110kW and depth from 170-230m

-

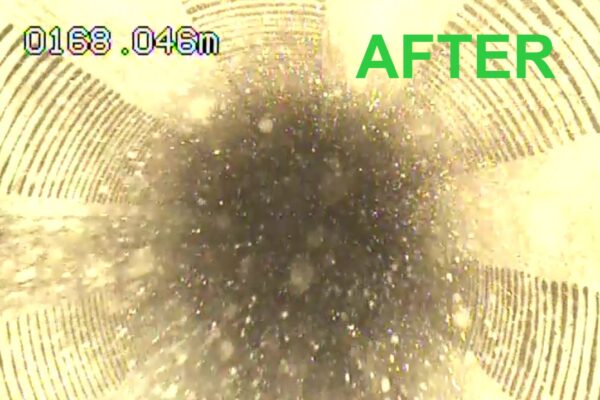

- Pre clean CCTV camera inspection

-

- Chemical dose the bores with Bore Saver C Solution and run cable tool brush down the bore to help dispurse liquid to the screened portion of the bore. Allow to soak

-

- Mechanicall scrub the bores using a specialised cable tool rig capabable of depth up to 300m

-

- Surge the bore using the cable tool rig and surge rubber assembly

-

- Bail the waste from the bottom of the bore use a bespoke bailing tool

-

- Re-install the pumping equipment and pump to waste until water runs clear

- Redirect water back into the mainline and commission the system

-